Cryogenic Generator Oxigen Generation Plants Hospital Oxygen Gas Plant Hot Sale

Description

Basic Info

| Model NO. | KDO |

| Usage | Nitrogen, Oxygen, Nitrogen/Oxygen |

| Purpose | Gas Manufacturing |

| Condition | New |

| Certification | ISO, CE, ISO14001/ISO45001 |

| After-Sales Service | Field Installation, Commissioning and Training |

| Technology | Cryogenic Air Separator Plant |

| Oxygen Purity | 99.6% |

| Nitrogen Purity | 99.99%-99.999% |

| Specification | 100-10000Nm3/h |

| Trademark | Chenrui |

| Origin | Hangzhou China |

| HS Code | 8419609090 |

| Production Capacity | 100 Sets Per Year |

Packaging & Delivery

Package size per unit product 300.00cm * 250.00cm * 150.00cm Gross weight per unit product 2500.000kgProduct Description

Chenrui Cryogenic Generator Oxigen Generation Plants Hospital Oxygen Gas Plant Hot Sale Product Description

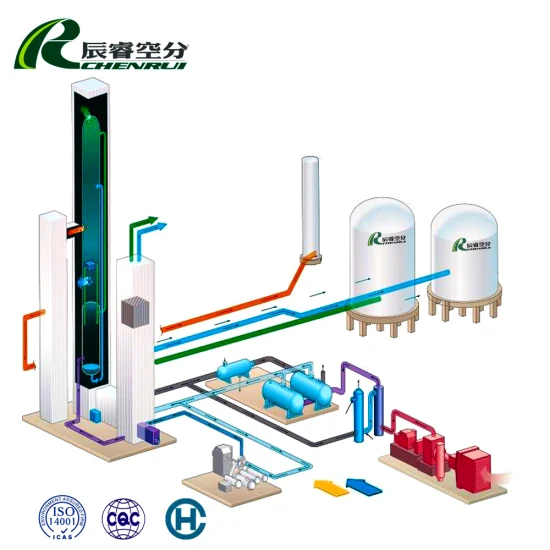

Air liquefaction by turbo expander refrigeration cycle principle.According to the different liquefaction point of oxygen and nitrogen,we get high pure nitrogen gas (nitrogen purity 99.99%)and oxygen gas(oxygen purity 99.6%after second rectification.It also could get some liquid gas.Acoording the principle of molecular sieve absorb,cooling by gas expender,single tower rectification,get both nitrogen gas and liquid nitrogen.Capcity and pressure could as user's requirement.

| No. | Main part | Function |

| 1 | Air Compression System | Air be compressed to 0.5-0.7 Mpa by air compressor, Imported centrifugal air compressor, high efficiency, low consumption, stable and reliable operation |

| 2 | Pre-cooling System | The air is pre-cooled to 5-10ºC in the pre-cooling unit, and the moisture is separated. The original imported screw refrigeration compressor and the air-conditioning unit combined with all imported refrigeration components are equipped with a water separator, manual and imported automatic drains to drain water regularly. |

| 3 | Air Purification System | Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier. The purifier adopts a vertical single-layer bed with simple and reliable structure and low resistance loss; built-in filter, blowing off and purifier regeneration at the same time; high-efficiency electric heater ensures complete regeneration of molecular sieve |

| 4 | Fractionating Column System (Cold Box) | The heating, cooling, liquid accumulation and purification of the fractionating tower can be completed in one way, and the operation is simple, quick and easy. Adopt aluminum plate-fin heat exchanger, aluminum convection sieve plate tower, the entire fractionating tower equipment pipeline adopts argon arc welding, the tower body and main pipeline in the cold box are made of high-strength aluminum alloy or stainless steel to increase the strength , Reduce the torsion damage of the pipeline. The equipment brackets, pipes and valve brackets in the cold box shall be made of stainless steel or aluminum alloy. The cold box is insulated with pearl sand and slag wool to ensure that the loss of cold capacity is minimized. The cold box structure guarantees the overall strength and the requirements of anti-seismic and wind resistance, and guarantees the load-bearing capacity of the cold box. When the cold box is running, it is equipped with airtight protection and safety devices. The main equipment in the cold box is equipped with electrostatic grounding. The cold valve and pipeline in the cold box all connections are welded, and flange connections are avoided. |

| 5 | Turbo Expander System | The air expands and cools in the turbo expander and provides the cooling capacity required by the device.The turbo expander adopts gas bearing, which is simple and reliable, easy to operate, and high efficiency. The cold box of the expander is set separately for easy maintenance. |

| 6 | Heat Exchange System | The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature; |

| 7 | Filling System | Single gas production: Internal compression process ( Cryogenic liquid pump, High pressure vaporizer, Filling manifold).Multi-gas production: External compression process (Oxygen & nitrogen & argon booster, Filling manifold). |

| 8 | Instrument and Electric Control System | Siemens imported brand, Fully automatic production system, Digital control system |

| 9 | Others | Equipment layout drawing (according to civil engineering design), Process pipe design drawings, Instrument electrical design drawings, etc. |

Cryogenic air separator plant specifications

| Model | Oxygen capacity (Nm3/h) | Oxygen purity(%) | Oxygen outlet pressure | Nitrogen capacity (Nm3/h) | Nitrogen purity(%) | Nitrogen outlet pressure | Start-up time |

| KDON-50/100 | 50 | 99.6 | 20Kpa Or as user's requirement | 100 | <10 | 15Kpa Or as user's requirement | 12 |

| KDON-100/200 | 100 | 200 | 12 | ||||

| KDON-150/600 | 150 | 600 | 12 | ||||

| KDON-170/400 | 170 | 400 | 12 | ||||

| KDON-350/800 | 350 | 800 | 16 | ||||

| KDON-550/1200 | 550 | 1200 | 16 | ||||

| KDON-1000/1000 | 1200 | 1000 | 24 |

| Model | Nitrogen capacity (Nm3/h) | Purity (ppmo2) | Pressure (Kpa) | Liquid nitrogen capacity (L/h) | Liquid nitrogen purity (ppmo2) | Air capacity request (Nm3/h) | Working pressure (Kpa) | Working cycle time |

| KDN-50 | 50 | ≤5 | 0.7 | / | / | 195 | 0.95 | 6 |

| KDN-100 | 100 | 0.7 | 360 | 0.95 | 6 | |||

| KDN-300/20Y | 300 | ≤3 | 0.63 | 20 | ≤3 | 1100 | 0.8 | 12 |

| KDN-600/30Y | 600 | 0.63 | 30 | 1800 | 0.7 | 12 | ||

| KDN-800/40Y | 800 | 0.23 | 40 | 1800 | 0.7 | 13 | ||

| KDN-100/50Y | 1000 | 0.23 | 50 | 3200 | 0.7 | 14 | ||

| KDN-2000/100Y | 2000 | 0.6 | 100 | 5500 | 0.7 | 15 | ||

| KDN-3000/25Y | 3000 | 0.6 | 200 | 7000 | 0.7 | 16 |

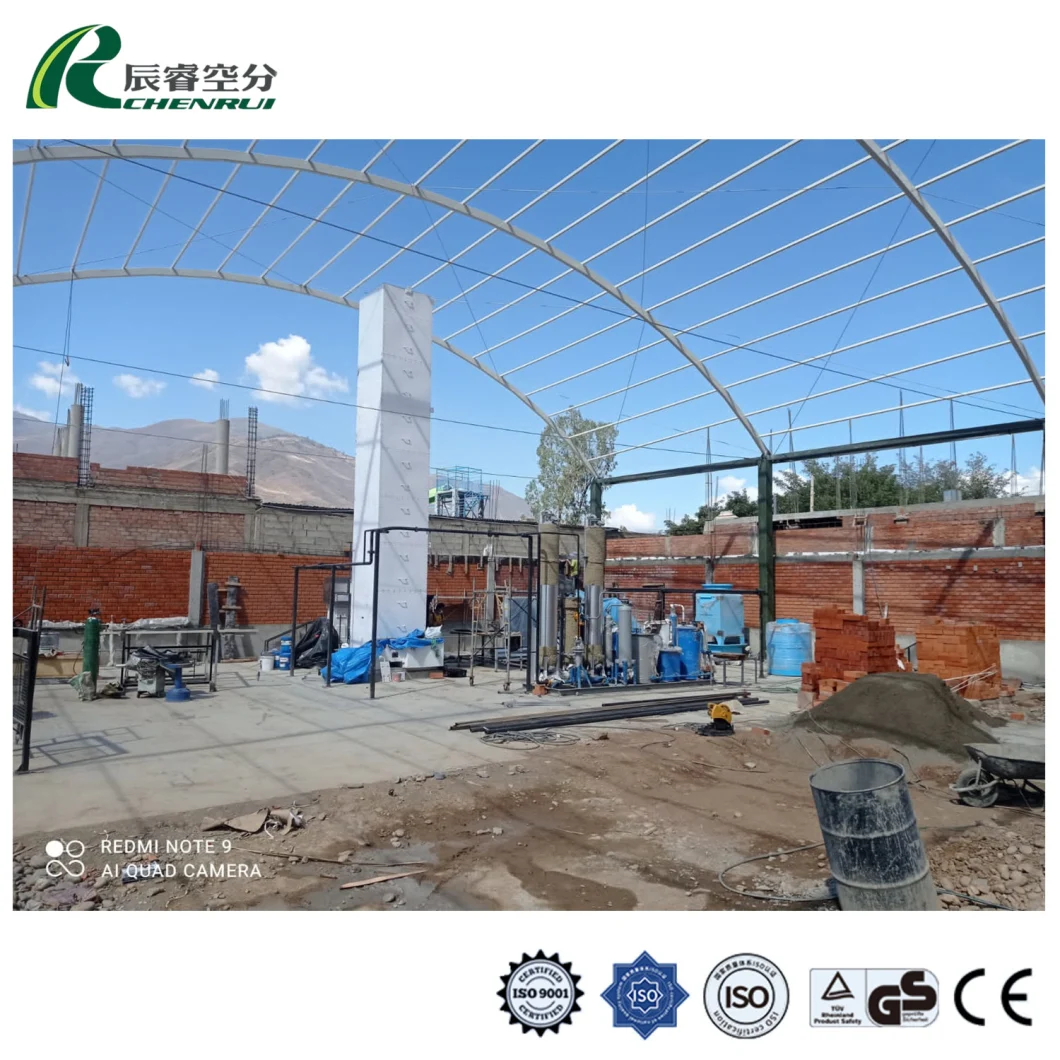

CertificationsOur exhibition and customers

Packing and shippingFAQ

1. Are you manufacturer or trade company?Hangzhou Chenrui is a professional manufacturer in oxygen generator, nitrogen generator, liquid nitrogen generator and air separator plant field for more than 20 years.2. What about production time?Liquid nitrogen generator production time is 90 days.3. What about quality?We have export to more than 30 countries with good reputation around our customers, quality is the first for our factory.4. What about order process?

a. Inquiry---provide us all clear requirements.b. Quotation---official quotation form with all clear specifications.c. Contract confirmation---provide correct contract details.d. Payment termse. Productionf. Shippingg. Installation and commissioning

5.Terms of payment?

We have flexible and active payment terms.6.How to get a promot quotation of oxygen generator?

When you send an inquiry to us, pls kindly send below technical information:1) Liquid nitrogen generator capacity : _____L/hr2) Liquid nitrogen purity: _____%3) Voltages and Frequency : ______V/PH/HZ5) Application:6) Project Location:

7. Could we as your agent?

Yes, of course. We are looking for sole agent in some Country who have the willing to cooperate with us for long business term.

Our Contact