Chenrui Onsite Cryogenic Air Separator Oxygen Generation Plant Machine Production Line for Hospital Oxygen Production Plant

Description

Basic Info

| Model NO. | KDO |

| Certification | ISO |

| After-Sales Service | Provided |

| Accept Custom | Yes |

| Technology | Cryogenic Air Separator Plant |

| Marketing Type | New Product 2022 |

| Specification | 95-99.999%/90-99.6% |

| Trademark | chenrui |

| Origin | Hangzhou China |

| Production Capacity | 10 Sets Per Year |

Product Description

Chenrui Onsite Cryogenic air separator Oxygen generation plant machine production line for hospital oxygen production plantProduct Description

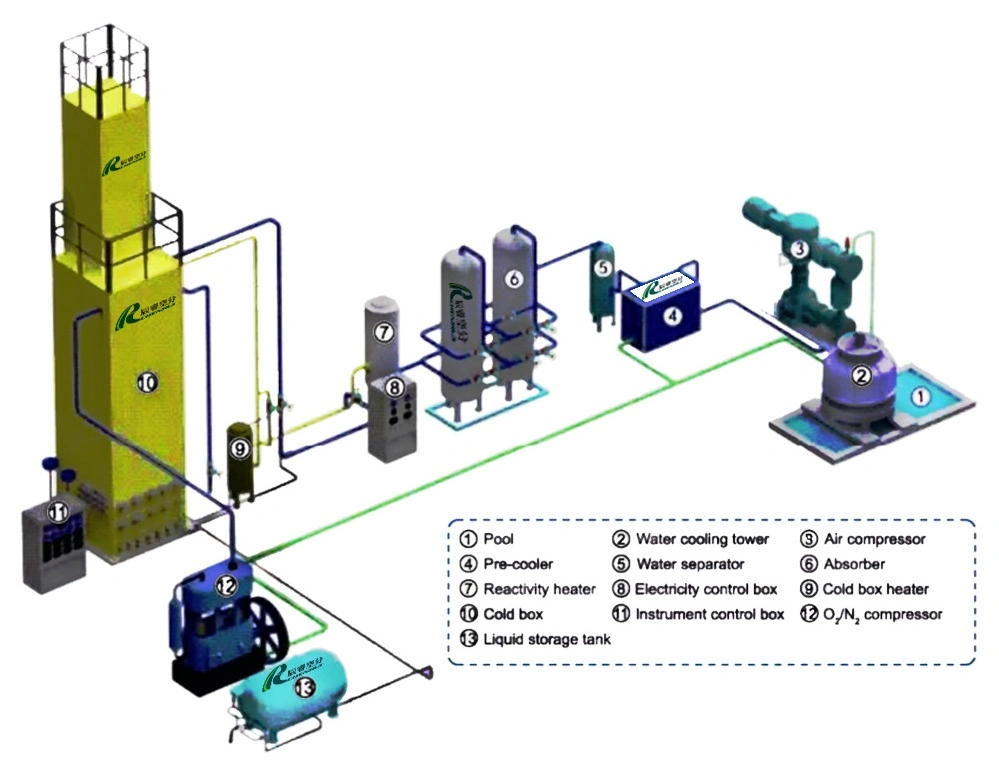

Principle of Operation

Cryogenic air separator plant principleAir liquefaction by turbo expander refrigeration cycle principle.According to the different liquefaction point of oxygen and nitrogen,we get high pure nitrogen gas (nitrogen purity 99.99%)and oxygen gas(oxygen purity 99.6%after second rectification.It also could get some liquid gas.Acoording the principle of molecular sieve absorb,cooling by gas expender,single tower rectification,get both nitrogen gas and liquid nitrogen.Capcity and pressure could as user's requirement.

Technical Parameters

| Model | Oxygen capacity (Nm3/h) | Oxygen purity(%) | Oxygen outlet pressure | Nitrogen capacity (Nm3/h) | Nitrogen purity(%) | Nitrogen outlet pressure | Start-up time |

| KDON-50/100 | 50 | 99.6 | 20Kpa Or as user's requirement | 100 | <10 | 15Kpa Or as user's requirement | 12 |

| KDON-100/200 | 100 | 200 | 12 | ||||

| KDON-150/600 | 150 | 600 | |||||

| KDON-170/400 | 170 | 400 | 12 | ||||

| KDON-350/800 | 350 | 800 | 16 | ||||

| KDON-550/1200 | 550 | 1200 | 16 | ||||

| KDON-1000/1000 | 1200 | 1000 | 24 |

| Model | Nitrogen capacity (Nm3/h) | Purity(ppmo2) | Pressure(Kpa) | Liquid nitrogen capacity (L/h) | Liquid nitrogen purity(ppmo2) | Air capacity request(Nm3/h) | Working pressure(Kpa) | Working cycle time |

| KDN-50 | 50 | ≤5 | 0.7 | / | / | 195 | 0.95 | 6 |

| KDN-100 | 100 | 0.7 | 360 | 0.95 | 6 | |||

| KDN-300/20Y | 300 | ≤3 | 0.63 | 20 | ≤3 | 1100 | 0.8 | 12 |

| KDN-600/30Y | 600 | 0.63 | 30 | 1800 | 0.7 | 12 | ||

| KDN-800/40Y | 800 | 0.23 | 40 | 1800 | 0.7 | 13 | ||

| KDN-100/50Y | 1000 | 0.23 | 50 | 3200 | 0.7 | 14 | ||

| KDN-2000/100Y | 2000 | 0.6 | 100 | 5500 | 0.7 | 15 | ||

| KDN-3000/25Y | 3000 | 0.6 | 200 | 7000 | 0.7 | 16 |

Technical Features

1). Full Automation

All systems are designed for un-attended operation and automatic Nitrogen demand adjustment.

2). Lower Space Requirement

The design and Instrument makes the plant size very compact,assembly on skids,prefabricated from factory.

3). High Reliabiity

Very reliable for continuous and steady operation with constant Nitrogen purity.Plant availability time is better than 99% always.

4). Molecular Sieves life

Expected Molecular sieves life is around 25-years i.e. whole life time of nitrogen plant.So no replacement costs.

5). Adjustable

By altering flow,you can deliver nitrogen with precisely the right purity.

1. Are you manufacturer or Trade Company?We are the manufacturer of Nitrogen Generator, founded in 20052. What's the order nitrogen generator process?a. Inquiry---provide us all clear requirements.b. Quotation---official quotation form with all clear specifications.c. Contract confirmation---provide correct contract details.d. Payment termse. Productionf. Shippingg. Installation and commissioning3.What terms of payment you use?T/T, L/C etc.4. How to get a prompt quotation of Nitrogen Generator?When you send the inquiry to us, pls kindly send it with below technical information.1) N2 flow rate: _____Nm3/hr2) N2 purity: _____%3) N2 discharge pressure: _____Bar4) Voltages and Frequency : ______V/PH/HZ5) Application and Project Location:

Prev: Hospital Oxygen Concentrator Medical Oxygen Concentrator Oxygen Concentrator Income

Next: 10 Liter Oxygen Concentrator Oxygen Concentrator Income

Our Contact