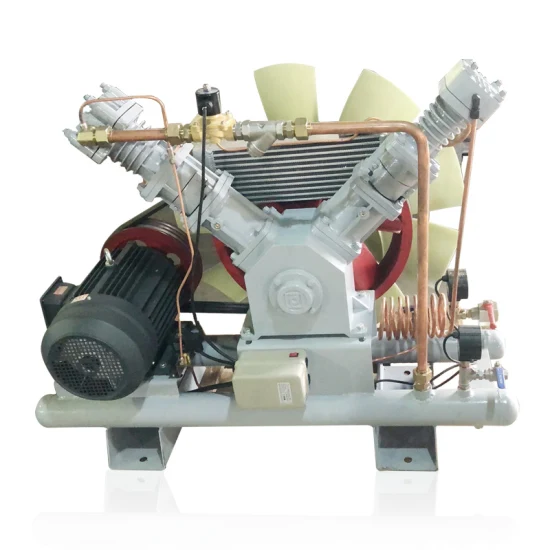

25 Bar High Pressure Oil-Free Oxygen Nitrogen Booster Compressor

Description

Basic Info

| Model NO. | VWN-60/4-25 |

| Cooling System | Air Cooling |

| Cylinder Arrangement | Balanced Opposed Arrangement |

| Cylinder Position | Angular |

| Structure Type | Closed Type |

| Compress Level | Double-Stage |

| Refrigerant Type | Freon |

| Flow Rate | 60m3/H |

| Intake Pressure | 4bar |

| Exhaust Pressure | 25bar |

| Power | 11kw |

| Weight | 260kg |

| Transport Package | Customized Wooden Box Packaging |

| Specification | 1250*700*900mm |

| Trademark | ROCKY |

| Origin | Shanghai |

| Production Capacity | 10000set/Month |

Packaging & Delivery

Package size per unit product 125.00cm * 60.00cm * 90.00cm Gross weight per unit product 260.000kgProduct Description

Oil Free 200 bar High Pressure Oxygen Compressor Nitrogen Compressor Booster with CE Approval

Our oxygen booster gas compressors feature the following:

1. No oil, no oil required, stainless steel cylinder

2. No pollution, keep the gas purity unchanged

3. The quality is safe and reliable, and the stability is good.

4. Low maintenance cost and simple operation.

5. The service life of the piston ring under low pressure conditions is 4000 hours, and the service life of piston rings under high pressure conditions is 1500-2000 hours.

6. According to the customer's specific working conditions, the compressor is designed as single-stage compression, two-stage compression, three-stage compression and four-stage compression.

7. Low speed, long life, average speed 260-400RPM.

8. Low noise, the average noise is lower than 75dB, it can work quietly in the medical field.

9. Continuous continuous heavy-duty operation, which can run stably for 24 hours without stopping (depending on thespecific model)

Technical paramete

| Number | Item | Parameter | |||

| 1 | Medium | Nitrogen (must be dry and particle-free gas) | |||

| 2 | Model | WWN-60-4-25 | |||

| 3 | Rated Flow (Standard State) | Nm3/h | 60 | ||

| 4 | Inlet temperature | ≤40 | |||

| 5 | Intake Pressure | MPa | 0.4 | ||

| 6 | Exhaust Pressure | MPa | 2.5 | ||

| 7 | Cylinder * Quantity | mm | Φ90+φ50 | ||

| 8 | Speed | r/min | 720 | ||

| 9 | Cooling Method | Air Cooling | |||

| 10 | Lubrication Method | Without Oil Lubrication | |||

| 11 | Compression Stages | Two Stage | |||

| 12 | Structure Type | Angle type, V type | |||

| 13 | Motor Power | 11 kw | |||

| 14 | Driven Method | Belt Drive | |||

| 15 | Installation Type | Basic Type | |||

| 16 | Dual Pressure Controller | Intake 4-5 | |||

| 17 | Control | Without oil lubrication, air cooling, reciprocating piston type | |||

| 18 | Connection Size | RC1" | |||

| 19 | Dimension(mm) | 1250*700*900 | |||

| 20 | Weight(kg) | 260 | |||

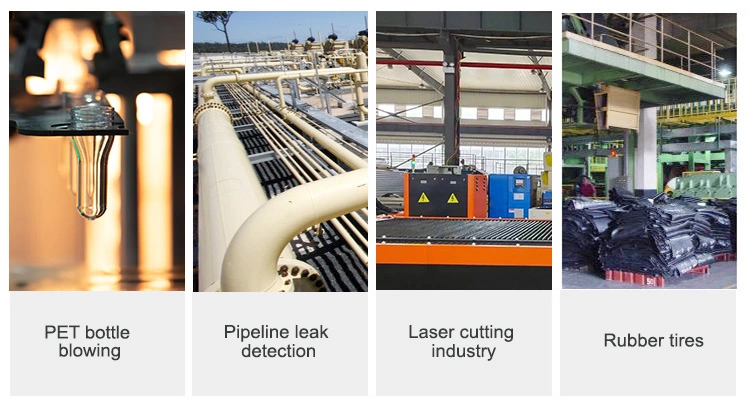

Industrial applications for oxygen compressors include booster use of low pressure oxygen for VISA applications in steel mills, paper mills and water treatment plants.

Shanghai Rocky Machinery was established in 2003 and has 18 years of experience in the air compressor industry. It is an innovative enterprise integrating production, trade, service, research and development.

Our company dominates strong technical skill, advancing manufacture equipment and testing device, execute strictly of ISO9001 quality management system. As a CE certificated manufacturer, our Oil-free series air compressor also reaches Germany TUV Class 0 standard. Main products have passed the testing of national technical authorities, energy consumption level has reached the international advanced level. With more than 120 skilled employees and 18 senior engineers, each production process is performed standardly and strictly. Germany technology and 14 years export experience have helped us to gain more than 30 loyal overseas agents, and our valued customers have spread across more than 130 countries.Rocky will continue to promote technological innovation and progress in line with the mission of "innovation reflects value", and achieve win-win results with global partners, suppliers and employees. Create a new world of "energy saving, envir-onmental protection and intelligence" in the field of air compressors.Packaging & Shipping

• Packing Details: Plywood crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary screw air compressor)

• Shipping method: by sea, by LCL/FCL or as requested• Delivery method: FOB, CFR, CIF and EXW etc.• Delivery time: in 7-15 days after receiving deposit (customized machines not included)After Sales Service1. 24/7 after sales service support in different languages.

2. Customized color, Model ect.3. Guidance of installation and commissioning on site can be provided by factory-trained technicians or local Authorized Service Center.

4. Delivery on time and excellent after-sales service.

5. Plenty of original spare parts with proven quality.

6. All kinds of technical documents in different languages.FAQ

Q1. Are you trading company or manufacture ?

A: We are professional manufacture of screw air compressor of Taicang,Jiangsu,China. More than 18 years of experience in air compressor manufacturing.Q2. How long is the delivery time ?

A: For standard voltage ,15 working days. Non-standard ,please contact our sales.

Q3. What's payment term ?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc. Also we could accept USD, RMB, Euro and other currency.

Q4. How about your after-sales service ?

A: 1.Provide customers with installation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3.Worldwide agents and after service avaiable.arrange our engineers to help you training and installation.

Q5. How about your warranty?

A: One year for the whole machine and two years for screw air end, except consumable spare parts.

Q6. Do you have any certificate ?

A: Yes, per different customer's market need ,we can offer CE ,ISO etc certificate.

Q7. What about the maintenance ?

A: First maintenance need to be done after 500Hours, and then every 2000-3000 hours to do the normal maintenance, and consider the actual environment.

Q8. How do you control quality ?

A: 1. The raw materials are strictly inspected

2. Some key parts are imported from overseas

3. Each compressor must pass at least 5 hours of continuous testing before leaving the factory.

Q9. Do you offer OEM service ?

A: Yes.Both OEM & ODM service can be accepted.

Q10.How long could your air compressor be used?

A: Generally, more than 10 years.

Prev: German Technology High Efficient VW Series Nitrogen Compressor Piston Compressor

Next: Inflammable Explosive Gas Recovery H2 Gas Compressor Hydrogen Compressor

Our Contact